As a big fan of Parmesan cheese (Parmigiano Reggiano), I have always dreamt of visiting an authentic Italian cheese factory and witnessing the production firsthand. During my trip to the northern region of Italy, Emilia-Romagna, I asked my colleague and guide, Natalya Miroshnikova, to arrange a visit to a cheese factory.

I was fortunate to visit one of Italy’s finest cheese factories, where I witnessed nearly every stage of the preparation of this renowned cheese. As a bonus, I also got to see the largest private collection of rare automobiles and tractors. Now, you might wonder, what do cars and tractors have to do with it?

I invite you to take a look at the photo report:

At dawn, we arrived at the organic cheese factory, albeit slightly late for the milking of the cows, which typically takes place between 5:00 AM and 6:00 AM. However, we did catch a glimpse of the milking parlor being cleaned. I was amazed by the impeccable cleanliness and even sterility of the premises.

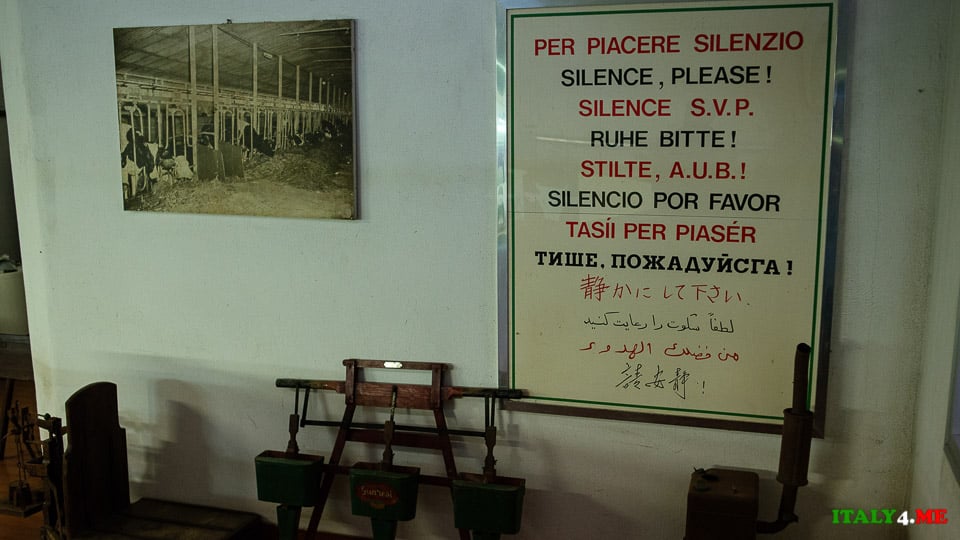

On the walls, alongside historical photos of the cowshed, there are notices requesting to maintain silence. The cows should not be disturbed or experience even the slightest stress.

Once again, I would like to draw attention to the floor – it is clean and adorned with original granite tiles. We will take a closer look at the cowsheds a little later.

The production of Parmigiano Reggiano in all cheese factories strictly adheres to the regulations of the Consorzio del Formaggio Parmigiano Reggiano. After the evening milking, the milk is transported directly from the milking parlor to the dairy plant, where it rests in tanks until the next morning. Once the skimmed milk is separated, it is combined with the morning milk in traditional copper vats shaped like an inverted bell.

Natural rennet and whey starter are then added to the milk to initiate the coagulation process.

Cottage cheese is broken down into tiny granules using an ancient tool known as the “spino” whisk.

After this process, the cottage cheese is slowly cooked, reaching a temperature of 55 °C (131 °F), and then the cheese granules settle at the bottom of the heater, forming a cohesive mass.

The assistant to the head cheesemaker prepares a special hemp cloth for extracting the cheese heads.

The profession of a cheesemaker in Italy, especially one responsible for Parmesan production, is prestigious and in demand. The work is physically challenging and requires the cheesemaker’s full commitment seven days a week, without any days off or vacations. Personal presence is mandatory for both morning and evening milking sessions, as well as numerous responsibilities throughout the day. Sick leave is only possible in emergencies. Cheesemakers usually work continuously for 3-5 years. Afterward, they take a vacation for a year or more, or they leave the profession.

How much does a cheesemaker earn? Approximately 5000 euros per month, with little time to spend it.

To wrap the future Parmesan cheese head in hemp cloth, a special wooden paddle is used.

The cheese mass head is lifted and suspended on the surface of the vat.

The cheesemaker cuts the curd into two parts using a large knife.

Each vat contains about 1000 liters of milk and 2 cheese heads.

This is how the famous Parmesan begins its journey. It will take at least a year for it to mature and be ready for consumption.

Now it’s time to move on to the next step – whey extraction…

… and placing it into molds to form the cheese heads.

Each mold holds a head weighing approximately 25 kg (55 lbs).

The molds are covered with a wooden lid and periodically flipped to remove excess whey.

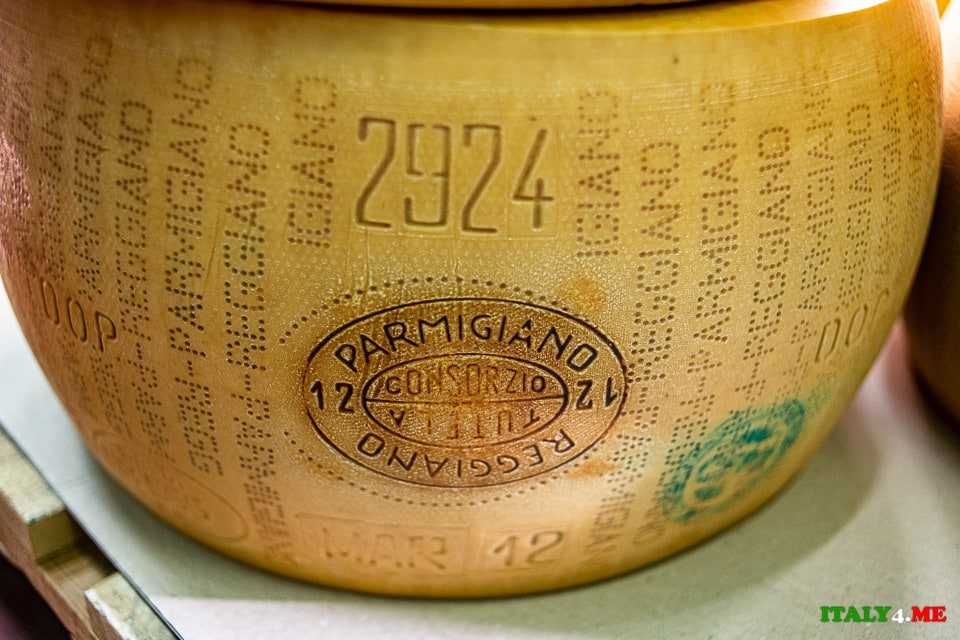

In the evening, the cheese heads are removed from the molds, and the cloth is placed in a special form for labeling. The cheese head must bear the date, name, and quality standard marking.

Then the cheese heads are immersed in brine (a solution of salt and water) for three days, which essentially is a process of osmosis.

This is the final stage of the production cycle, after which the aging process begins. Thus, on a daily basis, 7,000 liters of milk are transformed into 14 wheels of Parmigiano Reggiano, weighing 25 kg each.

- Read more about quality standards for food products in Italy.

On the way to the warehouse, we were allowed to peek into the cowshed and get acquainted with the car collection. But let’s go through everything step by step.

The herd consists of 500 heads of large horned cattle, half Frisian and half Piedmontese Red.

The farm covers an area of over 300 hectares, preserving natural pastures to improve the well-being of the animals. And indeed, the cows look very content.

The crop selection is based on the needs of the dairy cattle. The crop rotation is simple and is based on just a few crops, with the main one being alfalfa, which occupies over 60% of the grazing land. The remaining 40% consists of grains and legumes. All crops are grown according to the principles of organic farming, which prohibits the use of synthetic chemicals.

After interacting with the cows, we headed to the garage. I’m sure many of you collected sticker albums of cars, motorcycles, and football players in your childhood. But few knew or paid attention to the fact that the company behind these stickers is Panini.

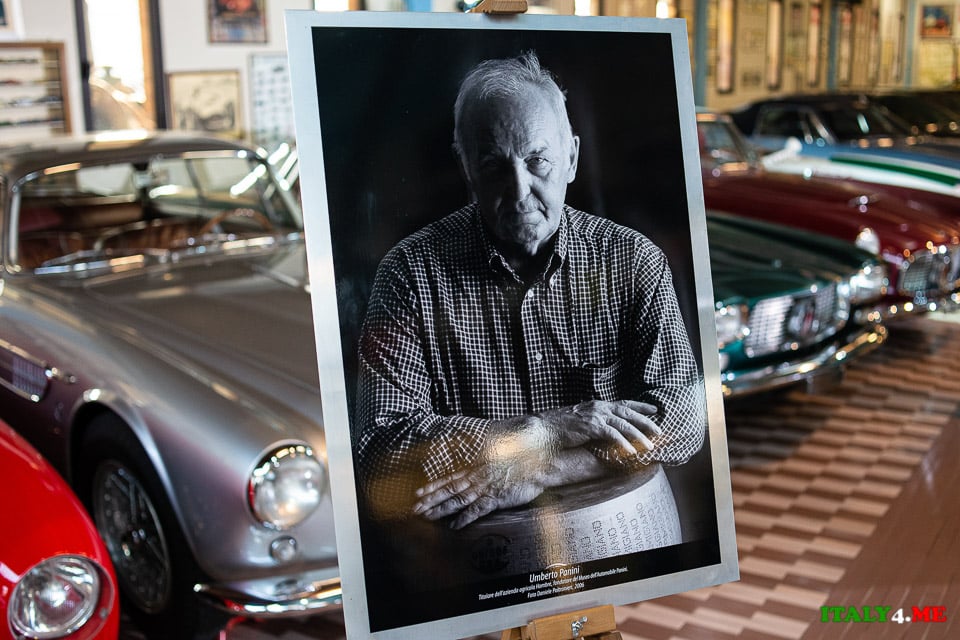

The owner of the farm, the renowned Italian entrepreneur Umberto Panini (1930-2013), was a great dreamer and co-owner, along with his three brothers, of the company www.paninigroup.com. With an annual turnover of around 500 million euros, the company thrives to this day.

So while we were buying stickers in our childhood, Mr. Panini was acquiring real cars.

The garage houses one of the world’s largest private collections of Lamborghini cars and tractors, as well as Maserati and other well-known sports car manufacturers.

During our visit, the crew from the Discovery Channel was filming another episode. In the photo below, I send a warm greeting to all those who are in love with Italy.

Of course, in addition to the dairy farm and the private car museum, there is a warehouse for aging Parmigiano Reggiano: a cool room with humid air where the cheese is stored after being removed from the brine.

The cheese wheels are arranged in rows and left standing on wooden boards in the warehouse. This allows the outer surface of the cheese wheel to dry, forming a natural, fully edible rind without any additional processing.

At the farm, they produce Parmesan cheese of three different ages, each with distinct sensory properties:

- Fresco (12-14 months), which has a simple milk base and a pronounced oily aroma.

- Stagionato (22-24 months), which has the most balanced taste that most people consider to be the classic Parmigiano Reggiano.

- Stravecchio (30 months and more), which has a distinctly granular structure and an intense flavor.

Every 15 days, the cheese wheels are cleaned and inspected. When the cheese reaches the age of 12 months, tasters (battitori) from the Parmigiano Reggiano Consortium arrive at the warehouse to “knock” on the cheeses and assess their quality.

What’s next? Once a minimum of 12 months has passed, and the cheese wheel is approved by the Consortium inspectors, it goes to the cutting department. First, the wheel is cut crosswise into two pieces.

Afterward, they cut it into rings about 4 cm thick.

A cylinder is then carved out from the central part. Now the cheese wheel resembles a wheel.

The cylinder cut from the center of the wheel is also packaged for sale. Obviously, it is more expensive than the traditional triangular piece.

Parmesan wheels are sliced into triangular pieces, like a pie.

Special knives are used for cheese slicing.

The triangular pieces are vacuum-sealed in portions of 100, 200, 250, 500, or 1000 grams.

How much does Parmesan cost from the manufacturer? Fresco – €14.50/kg, Scelto – €17.00/kg, Stravecchio – €21.50/kg. Prices in supermarkets and specialty stores are 20-50% higher.

Of course, you can try the cheese before purchasing. Personally, I prefer the 30-month-aged Stravecchio.

I hope this report from the cheese factory has further endeared you to the king of Italian cheeses – Parmigiano Reggiano.

For those who want to see the cheese factory with their own eyes, I recommend booking a private tour.

Italy for me From Italy with love

Italy for me From Italy with love